Introduction to Voronoi and Lattice Patterns

Voronoi and lattice structures have transformed the landscape of modern 3D printing and digital fabrication, empowering designers, engineers, and hobbyists to create advanced, efficient, and visually compelling designs. Offering a unique blend of structural robustness, significant weight reduction, and unparalleled visual intrigue, these patterns have become integral to cutting-edge manufacturing processes. Autodesk’s Meshmixer stands out as an indispensable tool that simplifies the generation and customization of these sophisticated designs, enabling users to leverage their full potential.

This extensive guide delves into the practical applications, methodologies, and optimization strategies associated with Voronoi and lattice structures, focusing specifically on Meshmixer’s rich feature set and capabilities.

Understanding Voronoi Patterns

What is a Voronoi Pattern?

Voronoi patterns, or diagrams, consist of partitioned cells or polygons generated based on proximity to specific “seed” points. Each polygon encompasses the area closest to its respective seed, creating distinct yet harmonious geometric patterns. Voronoi structures occur naturally in many biological systems, such as honeycombs, cell structures, and leaf veins, highlighting their inherent efficiency and aesthetic elegance.

Advantages of Voronoi Patterns in 3D Printing

- Structural Efficiency: Voronoi patterns naturally distribute stress, significantly enhancing overall structural resilience.

- Material Economy: They drastically cut down material usage, leading to lighter, more cost-effective prints without compromising structural integrity.

- Visual Innovation: Voronoi patterns provide exceptional visual intrigue, making them highly desirable for artistic, decorative, and architectural applications.

Exploring Lattice Structures

What are Lattice Structures?

Lattice structures consist of interconnected struts or beams arranged into repeated cellular geometries. These units vary significantly in size, shape, and density, providing unmatched flexibility for tailored structural performance. Industries such as aerospace, automotive, and biomedical engineering heavily leverage lattice structures due to their optimal strength-to-weight characteristics.

Benefits of Lattice Structures in 3D Printing

- Superior Strength-to-Weight Ratio: Efficiently supports mechanical loads without unnecessary material.

- Cost and Sustainability: Reduced material consumption leads to significant savings and supports sustainable manufacturing practices.

- Highly Customizable: Adjusting various parameters allows users to create designs precisely suited to specific performance criteria.

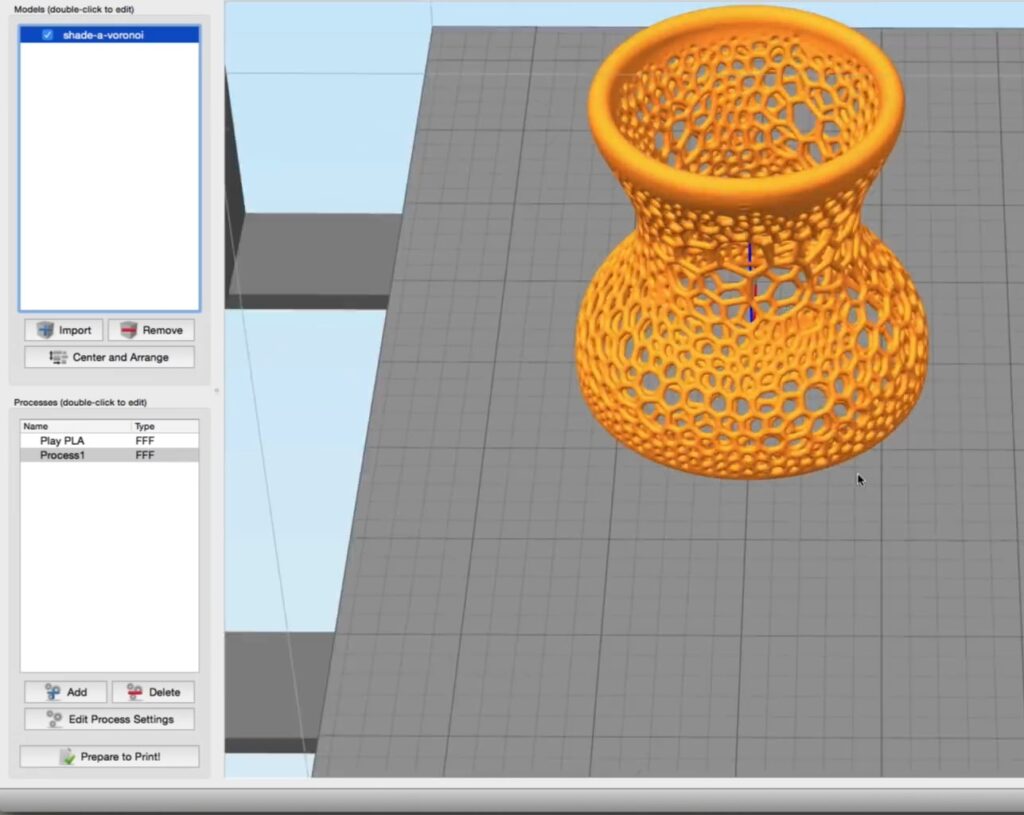

How to Generate Voronoi Patterns in Meshmixer

Step-by-Step Guide

- Import the Model:

- Launch Meshmixer and load your STL or OBJ file.

- Select Pattern Region:

- Highlight specific areas for Voronoi application using Meshmixer’s intuitive Select tool.

- Apply the Pattern:

- Navigate to Edit > Make Pattern.

- Choose Voronoi as your pattern type and fine-tune parameters including cell density, edge thickness, and smoothness.

- Preview and Confirm:

- Adjust parameters in real-time preview mode, confirming your design only when satisfied.

Best Practices for Voronoi Generation

- Density Management: Strive for optimal density to ensure printability and structural stability.

- Edge Thickness Considerations: Ensure sufficient edge thickness for strength and ease of printing.

- Edge Smoothing: Smooth edges minimize stress concentration and improve aesthetic outcomes.

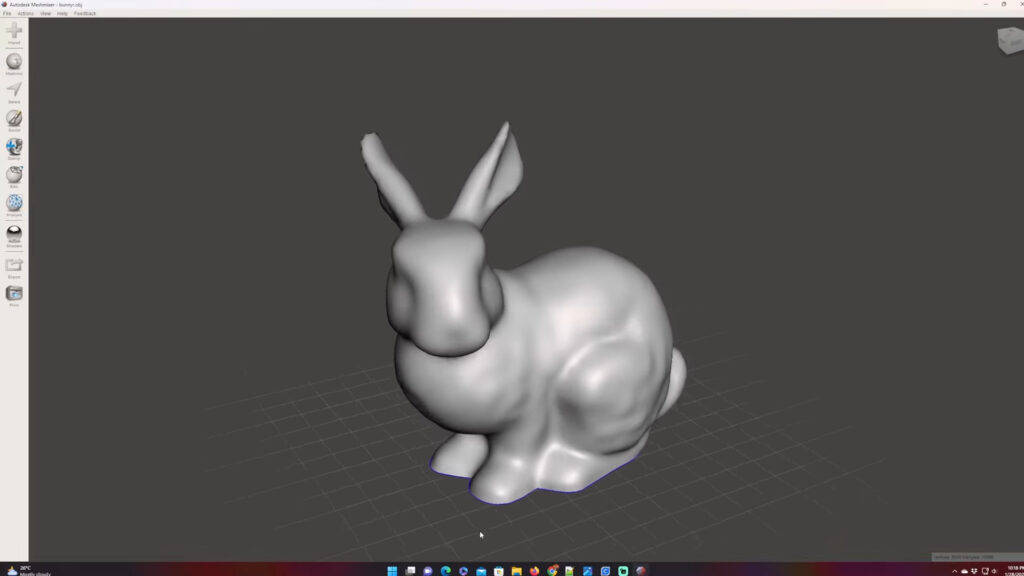

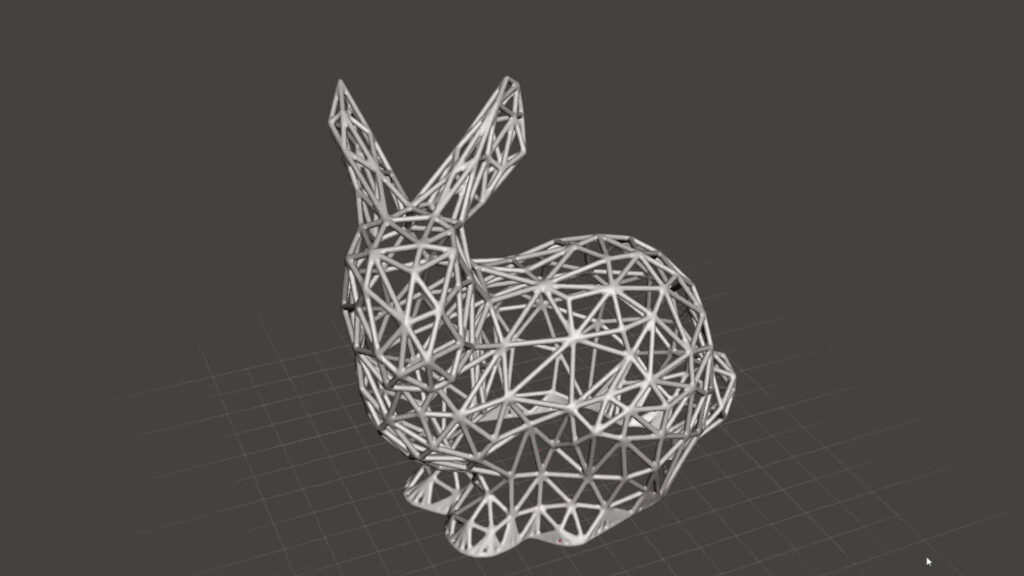

Creating Lattice Structures with Meshmixer

Step-by-Step Guide

- Model Preparation:

- Ensure the model is clean and free of errors by utilizing Meshmixer’s Analysis > Inspector tool.

- Hollow the Model:

- Prepare the model for lattice insertion by creating a hollow interior (Edit > Hollow).

- Insert Lattice Structure:

- Navigate to Edit > Make Pattern.

- Choose Lattice and adjust parameters like beam thickness, cell size, and lattice density.

- Finalize and Refine:

- Review and refine the lattice structure as needed using real-time visualization.

Strategies for Lattice Optimization

- Beam Thickness: Optimize beam thickness to ensure balance between strength and weight savings.

- Cell Dimensioning: Adjust cell sizes based on anticipated loads and material strength.

- Orientation: Align lattice patterns strategically for maximal load distribution and performance.

Real-World Applications of Voronoi and Lattice Structures

Aerospace and Automotive

These industries require high strength-to-weight ratios to enhance fuel efficiency and performance. Voronoi and lattice structures provide significant material reduction without compromising safety and reliability, crucial for innovative vehicle and aircraft designs.

Biomedical and Healthcare

Lattice-structured implants enhance healing by mimicking bone’s natural cellular structures, promoting better integration and patient outcomes. Voronoi patterns further enhance implant biocompatibility and structural performance, ideal for orthopedic and reconstructive applications.

Architecture and Interior Design

Modern architects and interior designers embrace Voronoi and lattice structures for their aesthetic sophistication, structural performance, and sustainable design possibilities. These patterns create distinctive, visually impactful elements, significantly enhancing contemporary architectural aesthetics.

Advanced Techniques for Voronoi and Lattice Enhancements

Hybrid Patterns

Combining Voronoi and lattice structures in a single design can yield superior structural and aesthetic results. Meshmixer facilitates seamless integration, enabling designers to experiment with hybrid configurations for optimal performance.

Gradient Patterns

Applying density gradients across patterns provides targeted structural performance, optimizing designs precisely for specific loads and stress profiles. Meshmixer’s intuitive controls enable gradual density transitions, balancing strength and weight effectively.

Troubleshooting Common Challenges

Structural Issues

- Cause: Thin beams, inadequate density, or inappropriate pattern choices.

- Solution: Adjust pattern parameters and beam thickness to enhance structural robustness.

Printability Problems

- Cause: Excessive pattern complexity or insufficient supports.

- Solution: Simplify the pattern, improve support placements, or adjust model orientation to enhance printability.

Visual Imperfections

- Cause: Sharp edges or abrupt transitions.

- Solution: Utilize Meshmixer’s smoothing functionalities and refine parameter settings for optimal aesthetics.

Expert Tips for Optimal Voronoi and Lattice Use

- Regularly utilize Meshmixer’s built-in analysis tools to assess model integrity.

- Perform test prints to ensure structural and aesthetic quality before scaling up to final production.

- Continuously refine your designs through iterative testing and parameter adjustments to achieve peak performance.

Conclusion

Voronoi and lattice structures in Meshmixer provide designers with powerful tools to create robust, lightweight, and visually sophisticated designs. By mastering the effective generation, optimization, and troubleshooting of these intricate patterns, users can dramatically enhance their projects’ quality and functionality. Incorporating these innovative methodologies into your design workflow enables you to leverage the full potential of contemporary 3D printing and digital fabrication, creating products that excel in performance, aesthetics, and sustainability.